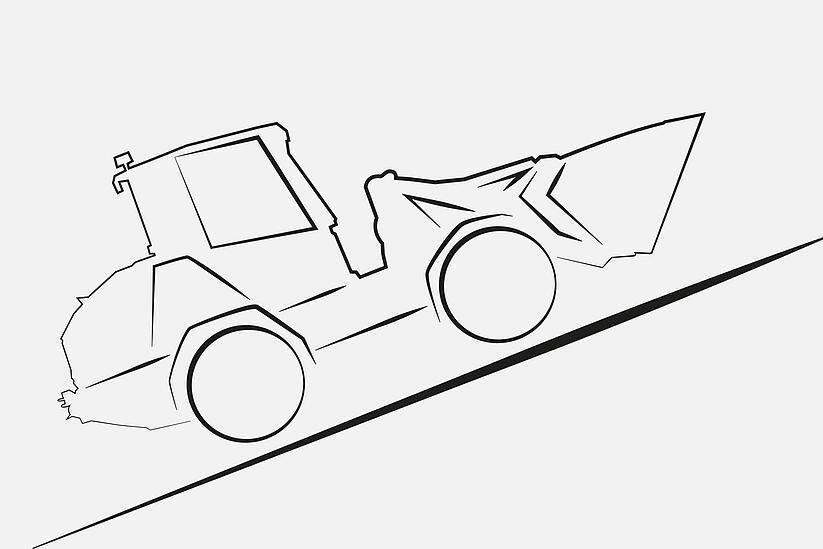

Next level: The compact wheel loader 2060 is characterized by simple standard equipment and sophisticated technology. The attractive price-performance ratio makes the machine the ideal entry model within its class of powerful wheel loaders. As a result of the great range of options, the machine can be perfectly adapted to your own requirements and needs. An operator’s canopy is installed as standard (optionally low/high) and a comfortable cabin is available with excellent ergonomics and all-round visibility as an optional extra. The following features characterize the 60-series: Simple entry and exit, electronic controlled drive system ecDrive with various operating modes, electric parking brake, sturdy central joint with optimized hose routing and very good maintenance access due to the transversely installed engine and optimized arrangement of the components.

Comfortable Cab

Service access front end

Motor installed transversely

Electric parking brake

ecDrive: Electronically controlled traction drive

Air-conditioning system