| Engine manufacturer | Perkins |

| Motor type | 404J-E22T |

| Cylinder | 4 |

| Drive output | 45 kW 45 kW |

| Drive output | 60.3 HP 61 PS |

| At max. rpm | 2,800 rpm 2,800 U/min |

| Cylinder capacity | 134.25 in³ 2,200 cm³ |

| Type of coolant | Water |

| Exhaust standard level | V |

| Exhaust aftertreatment | DOC/DPF |

| Operating voltage | 12 V |

| Battery | 77 Ah |

| Alternator | 120 A |

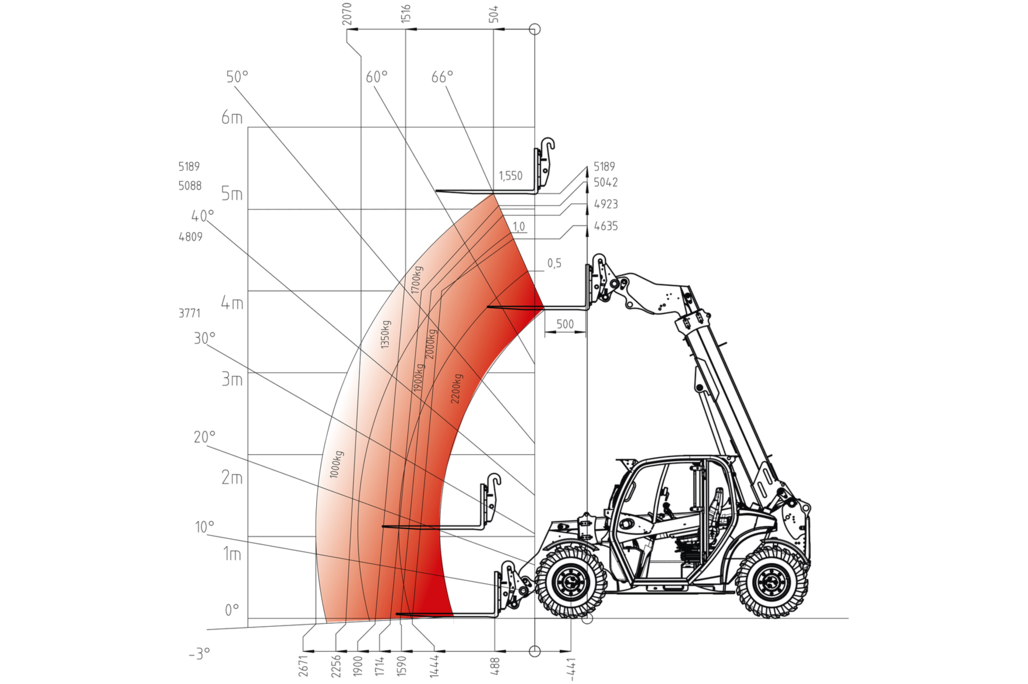

| Payload (max.) | 4,850 lb 2,200 kg |

| Operating weight | 9,259 lb 4,200 kg |

| Driver's cab | Cab |

| Tank capacity for fuel | 18.49 US gal 70 l |

| Tank capacity for hydraulic oil | 14.53 US gal 55 l |

| Type of drive | Hydrostatic |

| Drive unit | universal joint shaft |

| Speed levels | 2 |

| Axle | PAL 1530 |

| Travel speed Standard | 0-12,43 mph 0-20 km/h |

| Travel speed Option 1 | 0-18,64 mph 0-30 km/h |

| Operating brake | Hydrostatic drive system acting on all 4 wheels (wear-free) |

| Parking brake | Service and parking brake in the drive train acts on all 4 wheels |

| Differential lock | 100 % front axle + rear axle(option) |

| Drive hydraulics working pressure (max.) | 6526,7 psi 450 bar |

| Work hydraulics discharge volume (max.) | 18,49 (26,42) gpm 70 (100) l/min |

| Work hydraulics working pressure (max.) | 3263,35 psi 225 bar |

| Lifting cylinder | 1 |

| Tipping cylinder | 1 |

| Quick change system | Mechanical (hydraulically activated) |

| Steering type | Hydrostatic all-wheel steering with end position synchronization |

| Steering cylinder | 2 |

| Steering angle max. | 2x40 degree |

| Oscillating angle of the rear axle | ± 8 degree |

| Average sound power level LwA (operator's canopy) | 99.8 dB(A) |

| Guaranteed sound power level LwA (operator's canopy) | 101 dB(A) |

| Specified sound pressure level LpA (operator's canopy) | 77 dB(A) |

| Free text |

DPF = diesel particulate filter DOC = diesel oxidation catalyst SCR = selective catalytic reduction |

When the loader is used in accordance with the intended purpose, the whole body vibrations vary from below 0.5 m/s² up to a short-term maximum value.

It is recommended to use the values specified in the table when calculating the vibration values according to ISO/TR 25398:2006. In doing so, the actual application conditions are to be taken into consideration.

Telehandlers, like wheel loaders, are to be classified by operating weight.

Hand-arm vibrations: The hand-arm vibrations are no more than 2.5 m/s²

Whole-body vibrations: This machine is equipped with an operator’s seat that meets the requirements of EN ISO 7096:2000.

| Type of loader | Typical operating conditions | Mean value [m/s2] | Standard deviation (s) in [m/s2] | ||||||

|

| ||||||||

| Compact wheel loader (operating weight < 4500 kg) | Load & carry (load and transport work) |

|

| ||||||

| Wheel loader (operating weight > 4500 kg) | Load & carry (load and transport work) |

|

| ||||||

| Application in extraction (harsh application conditions) |

|

| |||||||

| Delivery drive |

|

| |||||||

| V-operation |

|

|