Friesian dairy operation: The principle of reliability – it simply needs to run smoothly.

The Milchhof Friesian GmbH and Co. KG in Göldenitz is about 30 km south of Rostock. Since September 2005, the Landman family has been running the large operation.

Oane Landman originally grew up on a farm in the Netherlands where he completed his apprenticeship and studied agriculture. He moved with his wife Willie to Mecklenburg-Vorpommern, to work as the manager of a large dairy operation initially for 10 years. The Landman family were able to realise their dream of owning their own farm in 2005: With the purchase of the business, they took on about 200 dairy cows, which produced 1.7 m kg milk per year at the time. However, it was not to stay like this forever. The business was systematically developed and expanded and the milk yield per animal could likewise be clearly professionally increased. Therefore currently there are around 1,300 dairy cows on the Friesian dairy farm and 1,100 animals in the breeding programme in different age classes.

There is a total of 13.5 m kg quality milk produced per year and marketed directly to different customers. Eight employees milk in shift patterns twice daily in dual-20-side-by-side milking parlour. Overall the Friesian dairy farm has 23 employees in the various different task areas, like e.g. crop production, herd management, biogas, feed, locksmiths, cleaning and servicing. Many apprentices and trainees, who would like to get to know a business within this size class, are likewise involved. The 923 ha cultivated area is distributed into 538 ha agricultural land (maize, agricultural grass and winter wheat) and 385 ha pasture land. Animal care is therefore at the forefront. From April to September the cows are likewise fed fresh grass. The animals are therefore optimally supplied with amino acids, as well as omega 3 and 6 fatty acids, and the feed production can be even more costeffective. This type of feeding has a very positive impact on the flavour of the milk and also the spreadability of the butter. With the connected 610 kW biogas system, their own power needs are covered.

Even the subsequent generation is already active on the Friesian dairy farm: Son Kees work in the field of plant production and daughter Wilma works in herd management. The second daughter, Annette, is studying business management and also energetically works on the farm. Oane Landman couldn’t have done much better: “We have the nicest job in the world: We are out in the open, we can live close to nature – we work with people and animals alike – what more could you want?!“ The business has an ideal location for milk production and the course for the future is set.

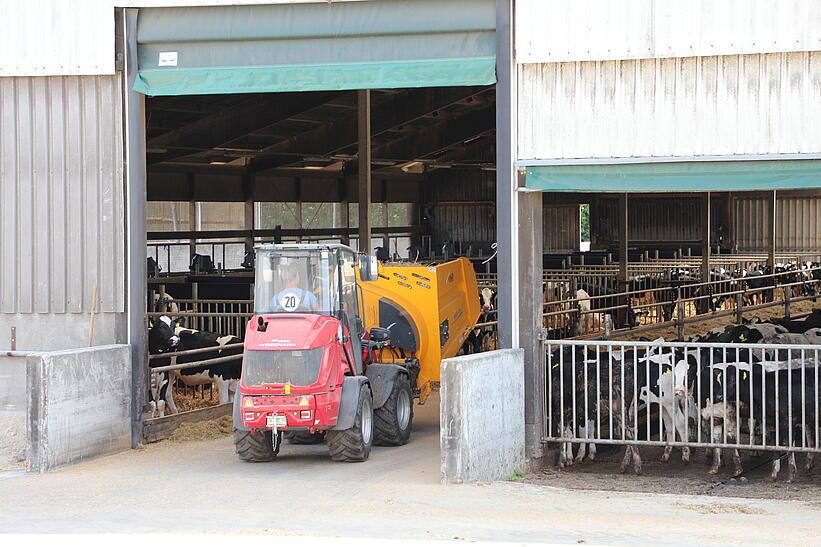

Five Weidemann machines care for the animals.

On the Friesian farm an extremely professional set-up is in demand: The first Weidemann joined the operation in 2018. Since then, the fleet has grown to a total of five machines. Three Hoftracs of the 13-series complete tasks like pushing in the feed, spreading the bedding and a whole load of transport works. The 7 m telehandler T7042 adopts the handling of around 5,000 square bales. On the extensive farm premises, you will come across the 9580T at the silo and the biogas system, which has to move around 112 t feed/ material per day and has completed around 8,000 operating hours in two years. “The machine have to be absolutely reliable and ready for use,” says Oane Landman. “If something should go wrong, we need a quick and easy solution and development.”

With the Weidemann distributor Seemann Landmaschinen from Groß-Roge, the business has therefore developed a close partnership over the years. Dirk Seemann provides the highest level of reachability with his 24/7 service and is completed service-oriented. “If you phone Dirk, he is there. There is no downtime,” explains Oane Landman with satisfaction. The matter of maintenance intervals must not fall short for a machine in such high demand. This is where the Weidemann telematics system, EquipCare, comes into play, with which the intervals can be proactively controlled at any time.