Agriculture and energy industry as an innovative mix

The Potthoff family from Velen (North Rhine-Westphalia) has a farm, operates a large photovoltaic system and uses a wheel loader with electric drive in the dairy cattle shed.

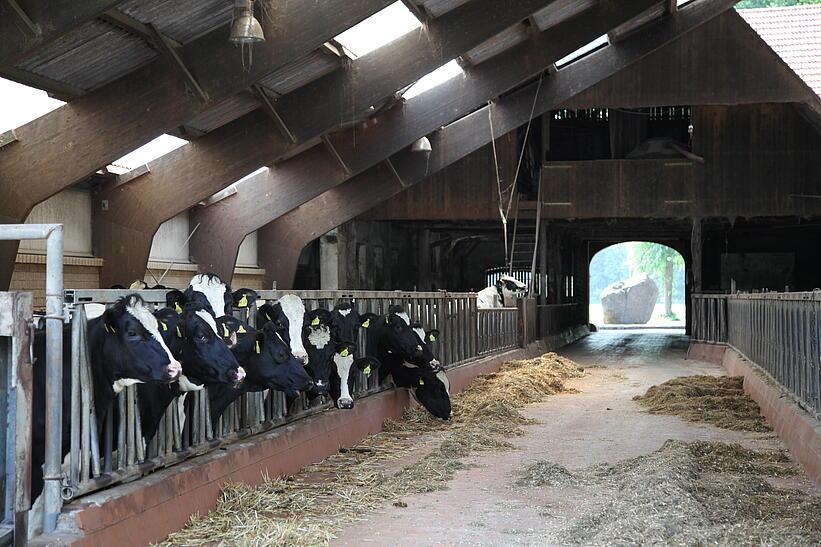

For a little over a year, the Potthoff family has owned two new Weidemann machines: a 4080 for heavy duty work, such as loading the feed mixer or loading large straw bales. In addition, there is a 1160 eHoftrac on the farm. Up until now, the diesel drive wheel loader had done all the work on the farm with 100 dairy cows. "However, we want to use as much power as possible from our photovoltaic system ourselves and were therefore very interested in a machine with an electric drive", says Stefan Potthoff junior, who runs the business together with his parents Heinrich and Maria Potthoff. The system on the roof of the large machine shop has 305 kW and produces significantly more electricity in the summer than is used in operation. May is the strongest month on average. The unused electricity is fed into the grid. Thanks to the size of the system, there is enough electricity to power the farm even on cloudy days.

"Firstly, we purchased a company car with an electric drive. Everything that we wanted to do with the vehicle could be covered with the 100 km range. That’s how we came upon the eHoftrac® by way of the electric car. It is used to do almost everything on the farm: from spreading hay in the stalls and cleaning the slotted flooring to pushing the feed and mucking out the calf igloos to sweeping the courtyard. It is our load and transport all-rounder par excellence. Everyone was excited about the multiple application possibilities, the acceleration behaviour and the freedom from exhaust emissions right from the start. It is also very quiet during operation", Stefan Potthoff continues. One thing the farmer appreciates about the electric drive: Since the traction drive is independent of the hydraulic pump, it can drive in “idle” and nevertheless utilize the full oil capacity, such as to spread hay or sweep. “With the diesel drive, on the other hand, I have to drive at full throttle in the barn with the noise and exhaust fumes that go along with it”, he says. In addition to the electric vehicles, an agricultural spray pump is also connected to the PV system for example and, of course, many other pieces of battery-powered equipment are in use on the farm, such as a trimmer, a cut-off saw, a conveyor board and much more.

Theoretically, it takes five hours to charge the 1160 eHoftrac battery. "But no work takes that long so that we can always recharge the loader at the charging station between uses and the machine is then always ready for us", explains Potthoff. Of course, two loaders are more expensive. But it's still worth it for the operation. "In the summer we have almost no electricity costs. In winter, however, the costs are around € 1,000 a month", says the farmer. In addition, the large wheel loader 4080 with a diesel drive wears less quickly and can be used correspondingly longer. Each loader is used exactly for what it was built in its size class, and this also makes economic sense. Because of the good experience with the electric loader, he would also buy a larger one with an electric drive. "We want to electrify as many drives as possible on the farm in order to be prepared for the time when the solar power system will no longer receive EEG [Renewable Energy Law] subsidies", he explains. In addition to the economic benefits, the company, which is currently switching to organic dairy farming, also wants to use the "green" drive for marketing purposes.