A perfect thing!

Nine-fold Weidemann power for the Baumschulgarten Enneking.

The Enneking family-run business in Damme now looks back on a company history of over 50 years in the tree cultivation and service industry. The company was founded by Heinrich Enneking in 1964, and is now being continued in the 3rd generation by Martin Enneking. The father-son business with one apprentice has developed into a large operation with more than 40 employees and 4 apprentices over the years. The first Weidemann Hoftrac came to the farm as a support back in the 1990s. More Weidemann machines continued to arrive in the following years, which were also replaced with the latest models again and again over the years.

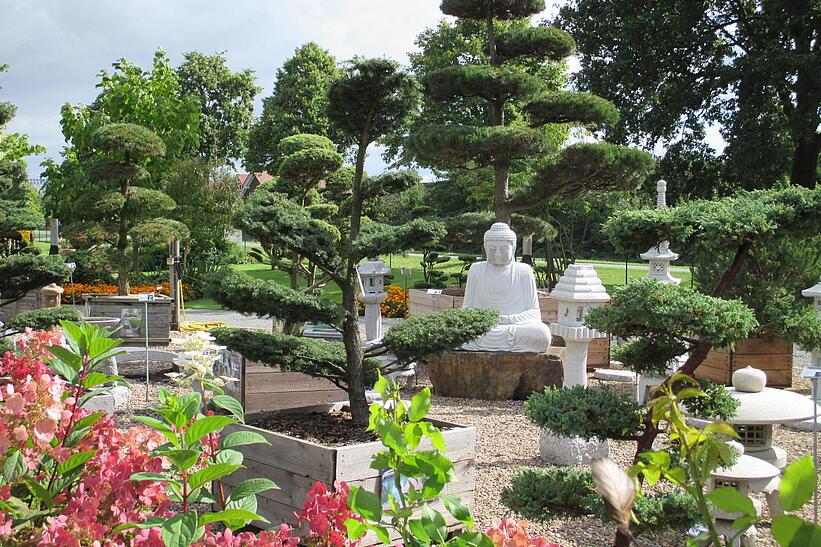

“I'm a very brand-loyal person. And because I'm very satisfied with Weidemann, we recently added a 3080T tele wheel loader to our Weidemann fleet”, says Managing Director Martin Enneking. Now, the farm has a total of nine Weidemanns: Seven Hoftracs (5 x 1350 and 2 x 1380), a 3080 wheel loader and the 3080T tele wheel loader. The garden center has a sales area of approx. 28,000 m² - so it is not surprising that mechanical support is required on a large scale. “The Hoftracs especially are great for being able to drive on the narrow tracks, get into little corners, and I can even transport them on a trailer. The ratio of operating weight to payload was also a deciding factor for us. That is superb with the machines”, explains Martin Enneking.

With such a splendid fleet, it is no wonder that the nursery garden has a large number of receptacles: Grab bucket, pallet fork, sweeping machine, hedge trimmer, pot grip, snow blade - just to name a few. The machines are mainly used for transport work in the operation: Be it stones, plants or trees - this is where the Weidemanns come into play. Also in activities such as hedge trimming, cemetery work or transplanting plants. The machines are used every day and average over 500 engine hours per year.

Go to next application report

A good neighbor.

What counts in professional football is also applicable to the horse…